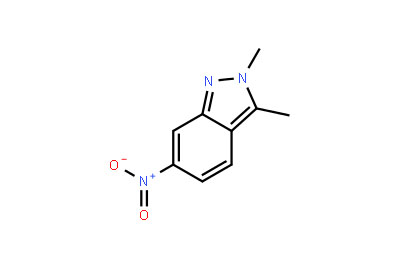

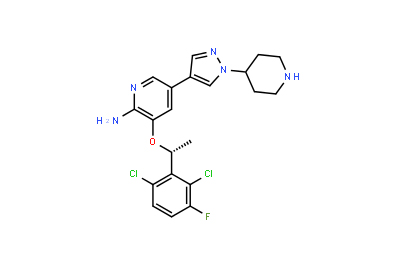

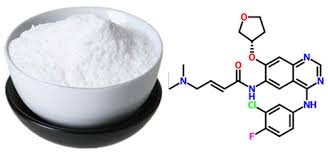

API intermediates from Intermediate Manufacturer are substances or agents that are utilized as raw materials in the production of active pharmaceutical ingredients (API). These intermediates are produced via amination, hydrogenation, alkoxylation, hydroformylation, electrochemistry, acetylene chemistry, phosgene chemistry, and other technologies.

The API intermediate industry is being driven by the increased acceptance of generic medications, and specialty medicine, a spike in demand for biopharmaceuticals, and a growth in abbreviated new drug applications. Furthermore, an increase in illness incidence and an increase in the elderly population prone to different diseases and disorders are expected to drive market expansion. R&D initiatives for the creation and enhancement of medications for chronic illnesses, as well as FDA approvals for novel compounds, give fresh market expansion potential.

The API intermediate market is divided into four sections: product, intermediate type, therapeutic use, and geography. It is divided into chemical intermediates and biotech intermediates based on the product.

The pharmaceutical sector is developing and renewing itself all the time. As the need for pharmaceutical intermediates from Intermediate Supplier China grows, a lot of pharmaceutical businesses and industry participants are adjusting to new sales methods.

What precisely are pharmacological intermediates?

Medicinal intermediates are fine chemicals that are created as intermediary compounds during the manufacturing of active pharmaceutical components (APIs). Intermediates are byproducts of the reactions that occur throughout the API manufacturing process. Depending on the analysis, each reaction in the manufacturing process may yield many intermediates that can be employed as precursors for additional active pharmaceutical components. Further refining methods can be used to convert intermediates to active components.

There are several variables and studies that separate active components and molecules from pharmaceutical intermediates. The final products of raw materials are active ingredients and specialty chemicals, whereas chemical intermediates from Intermediate Manufacturer China are byproducts of the API production process. Furthermore, unlike active substances that include particular compounds, intermediates are not subject to approval or regulation.

As global pharmaceutical activity grows, new inventions emerge and the need for pharmaceutical intermediates producers rises. The worldwide pharmaceuticals and packaging industry has expanded as a result of pharmaceutical businesses implementing regulated pharmaceutical operations.

Follow us on Facebook