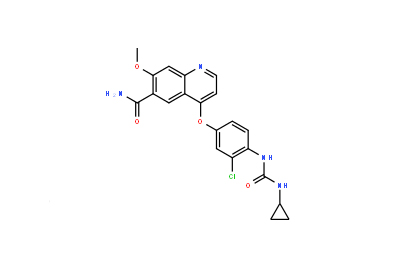

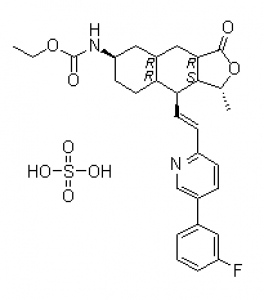

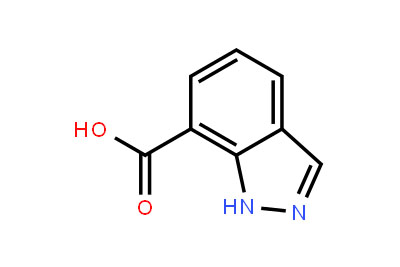

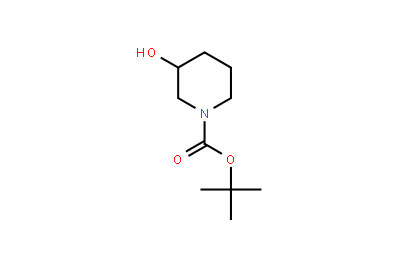

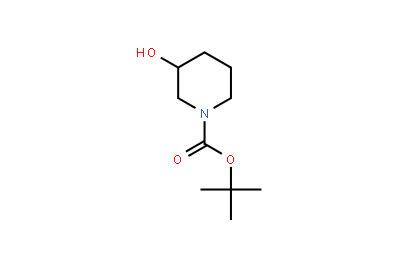

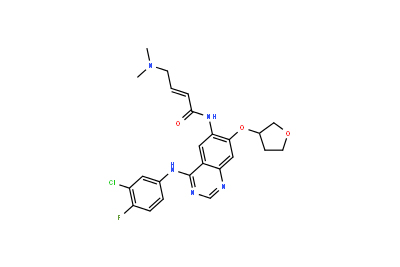

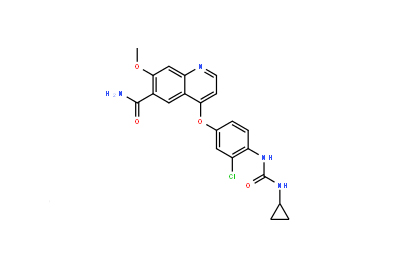

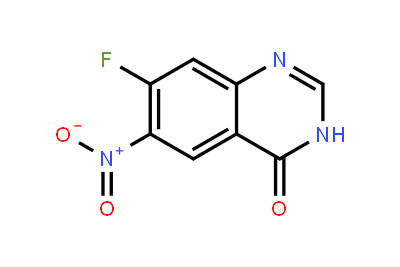

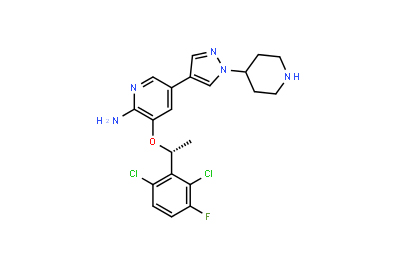

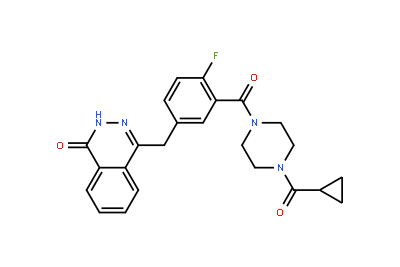

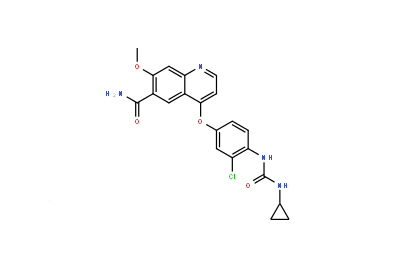

Chemicals have a significant part in altering our lifestyles and enhancing our health, having a daily impact on millions of people’s lives. The creation of active pharmaceutical ingredients by API manufacturing facilities was sparked and accelerated by the desire to enhance people’s health. Doctors and scientists from all over the world have invested a lot of time and energy in research and development in this area. By using active pharmaceutical components like Lenvatinib Intermediate in innovative ways and correctly, many surprising results have been revealed that may be found in well-known medical publications or websites.

Branded pharmaceutical intermediates are used by several reputable pharmaceutical businesses and are now a crucial component in production. Many of these businesses base their primary manufacturing lines on food additives and medication intermediates. In the past, API Pharma facilities were concentrated in western nations, from which they exported medications and other related goods to other nations. The current tendency is for emerging nations to actively participate in this process. These nations are now thought of as new locations for the production of API.

Active pharmaceutical compounds, whose use has nearly doubled in recent years, are a crucial component in the creation of cosmetics and pharmaceuticals. You can Buy Lenvatinib Intermediate online.

GMP is a prerequisite in the majority of pharmaceutical components and intermediates that are utilized to create the compounds. Since numerous biotech businesses now produce and sell active pharmaceutical ingredients online, finding these API Pharma has never been easier. These websites provide access to further information about these biotech businesses.

Due to the increase in worldwide attention toward environmentally friendly products, pharmaceutical enterprises with eco-conscious strategies have a higher opportunity of developing a global market. Active pharmaceutical ingredients that are created and of high quality will improve the medication production process. A reputable and good API Pharma firm adheres to all Western regulatory laws and regulations completely.

They can give comprehensive information on their technological know-how, production scope, quality control systems, business capacity, and manufacturing processes. They can supply active pharmaceutical ingredients like Lenvatinib Intermediate to numerous international businesses, R&D institutions, pharmaceutical firms, and other organizations. Expert scientific staff with the necessary training and expertise in the relevant sector should be present in an API production firm.

Follow us on Twitter