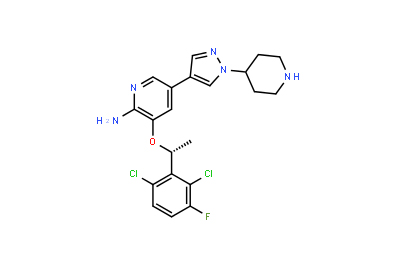

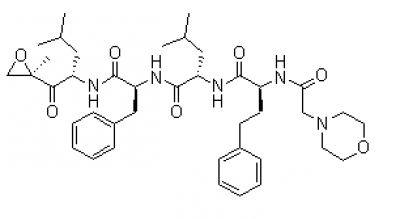

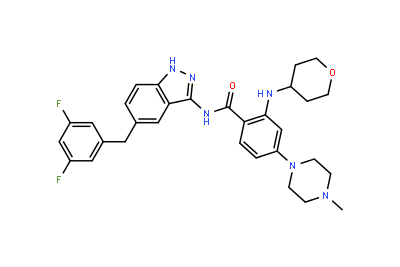

API (Active Pharmaceutical Component) from API Manufacturer Company China refers to the active ingredient found in pharmaceuticals. A painkiller, for example, has an active component that relieves pain. This is known as API. Because a little amount of the active component has an impact, just a trace amount of the active ingredient is present in the medication. On the packaging of OTC (over-the-counter) medications, you will discover the name and quantity of the active component.

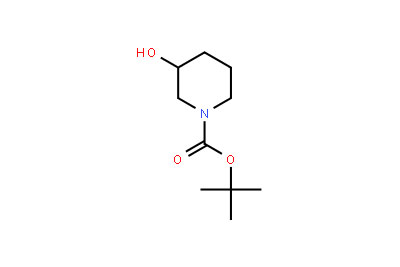

API and raw material are frequently mistaken due to their similar use. What is the distinction? Raw materials are chemical substances that are utilized as a starting point to create an API. Manufacturers buy raw materials from producers of raw materials and chemical products throughout the world. An API Manufacturer generates API in the plant’s huge reactor utilizing raw materials.

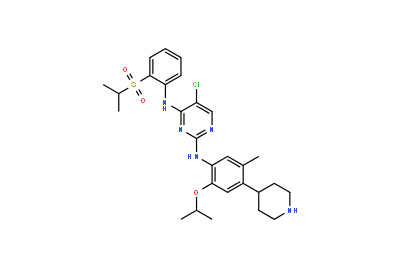

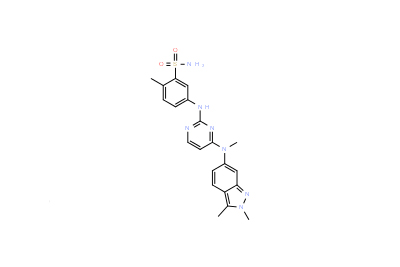

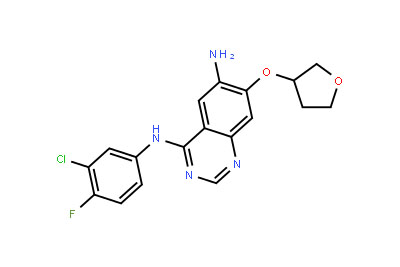

The API is created by a series of chemical reactions rather than a single reaction from basic components. An intermediate is a chemical compound that is in the process of switching from raw material to an API. Among the APIs developed, one goes through over ten different types of intermediates in the process of transitioning from raw material to API. Following this lengthy production process, it is refined to a very high degree of purity before becoming an API.

The active pharmaceutical ingredient (API) sector provides raw ingredients to pharmaceutical producers for later processing and formulation into saleable pharmaceutical products. Pharmaceutical drugs (drug products) are typically made up of two types of components: an active ingredient, which is either chemically active or has biological activity, and excipients, which are inert substances included in the product formulation that stabilize the active ingredient and make it more manageable. Other ingredients may be added to improve stability, solubility, or other qualities.

Large pharmaceutical manufacturers are progressively outsourcing portions of their supply chains, including constituent manufacturing, to more cost-effective vendors, according to recent API industry trends. The API Supplier China has generally been in China, resulting in a fast increase in API manufacturing capabilities.

Follow us on Facebook