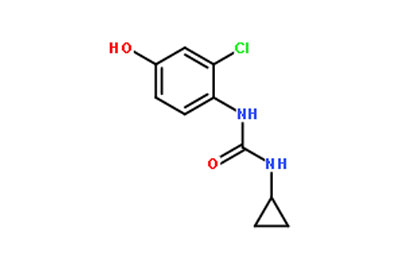

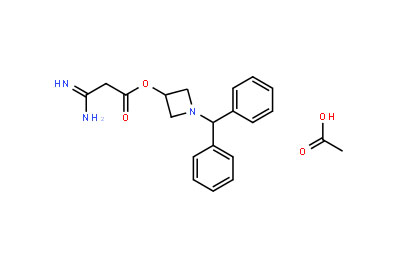

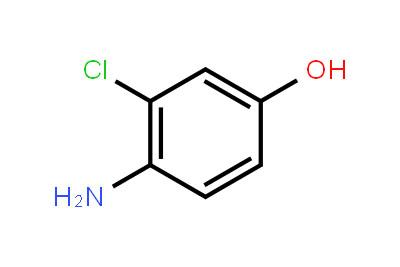

A molecule that is created from two or more reactants and undergoes further reactions to produce products is known as an intermediate from an Intermediate Manufacturer.

The majority of chemical reactions take more than one step, and each step, except the last one, when the end products are created, produces an intermediate. Since they are seldom isolated, they frequently interact with other compounds during the reaction to create the final products.

The foundation for final items is provided by intermediates or semi-finished products. The majority of end items require intermediates, which are used as a component in the creation of other commodities.

There are several intermediates used in the manufacture of every item you consume. A finished good can also serve as an intermediate for another good; intermediates don’t always have to be semi-finished goods. Every business depends on intermediate goods from Intermediate Supplier China, which are also a key source of raw materials for manufacturing.

Although they have comparable lifetimes, intermediates may be distinguished from molecular vibrations, which are essentially transitions. Because they are extremely reactive and have a short lifetime, intermediates are often present in very small amounts in reaction mixtures. We must, of course, consider the reaction in which the intermediates are present while defining them. A species that is deemed unstable in one reaction may be stable in another.

When compared to the other compounds involved in the processes, intermediates have a brief lifespan. Due to their great reactivity, they frequently take the form of free radicals or unstable ions and may need to be created at extremely high temperatures or pressures. In certain reactions, many stages are carried out in a single batch. Because of their strong reactivity with other compounds in the reaction mixture, it is sometimes unnecessary to isolate an intermediate for subsequent reactions, and other times it is impossible. Since intermediates have a very limited lifespan, it is difficult to distinguish between them.

In the chemical business, an “intermediate” from Intermediate Manufacturer China is often a reaction product that serves as a precursor chemical for another industry.

Follow us on Facebook