The chemical industry, biotechnology, and pharmaceutical industries may be categorized as the end users in the worldwide market for drug intermediates. Drug intermediates from Intermediate Manufacturer in several distinct varieties, including premium quality, high quality, and moderate quality intermediates. The high-end and premium intermediates are mostly employed in R&D projects.

Due to the quick discoveries and improvements taking place in the disciplines of life sciences and biotechnology, there have been rising demands for drug intermediates on the global market. The use of drug intermediates in research and clinical investigations has also increased, as have their adoption and applications.

Now more than ever, academic institutions, pharmaceutical and biotechnology companies, and other businesses are concentrating their R&D efforts on the design and development of new drugs. Additionally, they are putting a lot of emphasis on developing new tools, processes, and equipment for the synthesis of therapeutic intermediates. This will provide producers the freedom to offer highly customized synthetic medications in the future. Additionally, it has aided in broadening the range of its numerous uses, contributing to the expansion of the worldwide market for drug intermediates as a whole.

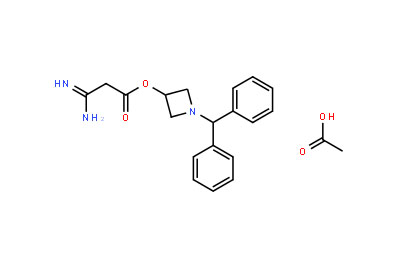

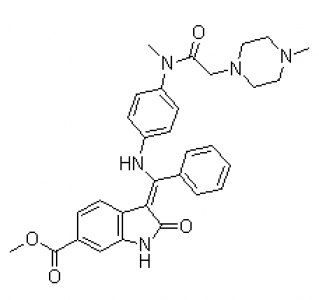

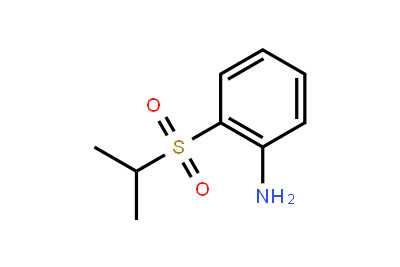

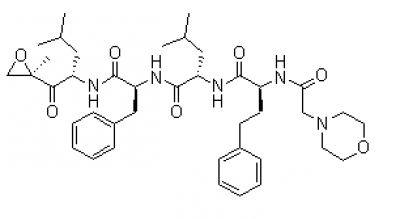

The active elements of a pharmaceutical medicine from Intermediate Supplier China that have the desired impact on the body to cure a condition are known as active pharmaceutical ingredients (APIs). Chemical substances are processed to create APIs. The active component of a biological medication is referred to as a bulk process intermediate (BPI). Due to the rising incidence of chronic illnesses including diabetes, asthma, and cancer, the API industry has seen some appealing potential despite high production costs, rigorous regulatory laws, and legislation in many countries restricting medicine pricing.

APIs may be divided generally into two groups: synthetic and natural. Based on the method of synthesis, synthetic APIs are further divided into a novel and generic synthetic APIs.

Small molecules, or synthetic chemical APIs, make up a significant portion of the pharmaceutical business and several small-molecule medications are offered for sale. Biologics, which are increasingly the most popular medications on the market, is made from natural APIs from Intermediate Manufacturer China. Despite the rising need, there are currently far fewer biologics available than small-molecule medications.

Follow us on Twitter