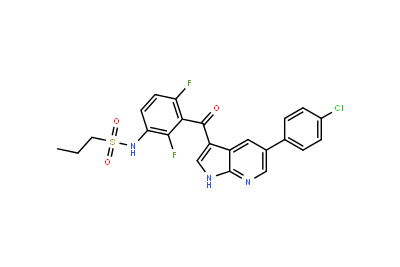

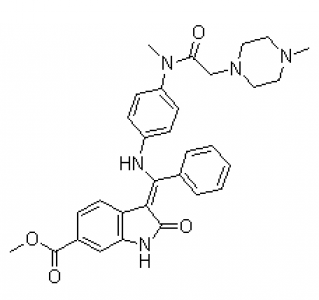

The term “active pharmaceutical ingredient” (API) from API Manufacturer refers to the substance that makes up a medicine. An active component in a painkiller, for instance, reduces pain. The medicine only contains a very little amount of the active component since it takes a very small amount of the active ingredient to have an effect. On the package of OTC (over-the-counter) medications, you may discover the name and quantity of the active component.

Due to the comparable use of these two phrases, API and raw material are frequently used interchangeably. What is the distinction? A chemical that serves as the foundation for creating an API serves as the raw material. An API is created from raw materials through a range of reactions rather than just one. Intermediaries are substances that are converted from raw ingredients into APIs. Some APIs pass through more than 10 intermediates before they are finished products.

Learning to Manage Risk Yet not all risks in API production by API Manufacturer Company China are caused by events beyond our control. Bad managerial supervision and human error may be major issues.

Every project should get off to a strong regulatory start. To create a regulatory strategy, API manufacturers should collaborate with internal teams, consultants, and sponsors. Optimized process chemistry, precise and dependable analytical techniques, and scientifically valid and defensible requirements that will direct the whole process—from development to manufacturing—are necessary for this. Projects may quickly run off the tracks without a clear grasp of the objectives and procedures that will govern them.

Be careful before making rash decisions. Everything should be done to guarantee that you can complete the project without going over budget; yet trying to save money nearly always backfires and has the opposite effect, such as delays that end up costing more money. Many sponsors may attempt to save expenses by hiring subpar facilities or API Supplier China from elsewhere.

Later levels require greater investment. There is a higher likelihood that a project is headed for commercialization when it has completed the learning stages and has produced unambiguous clinical findings and reliable funding.

Follow us on Facebook